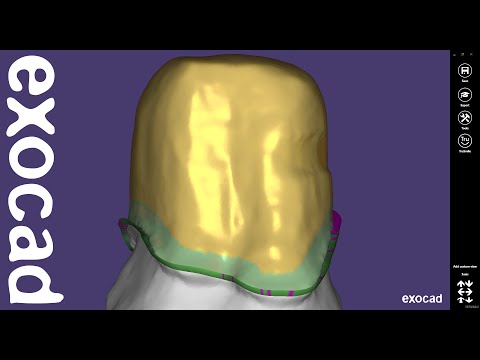

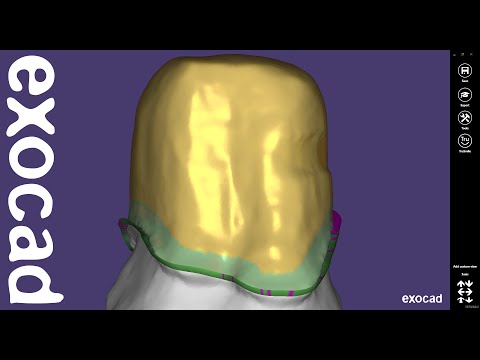

exocad快速指南。冠底 (exocad Quick Guide: Crown Bottoms)

沒有此條件下的單字

沒有此條件下的單字US /ˌɪndəˈvɪdʒuəl/

・

UK /ˌɪndɪˈvɪdʒuəl/

- n. (c.)個人;單個項目;個體;個人賽

- adj.個人的;獨特的;個別的;獨特的

US /məˈtɪriəl/

・

UK /məˈtɪəriəl/

- n. (c./u.)布料;素材;資料;材料;物質

- adj.重要的;物質的

- n. (c./u.)大小;規模;魚鱗;比例;等級;標尺

- v.t./i.測量;攀登;魚鱗

US /ˈnɛɡətɪv/

・

UK /'neɡətɪv/

- n.負電極的;否定詞;否定句;底片

- adj.消極的;負的;負面的;否定的;陰性的;負電的