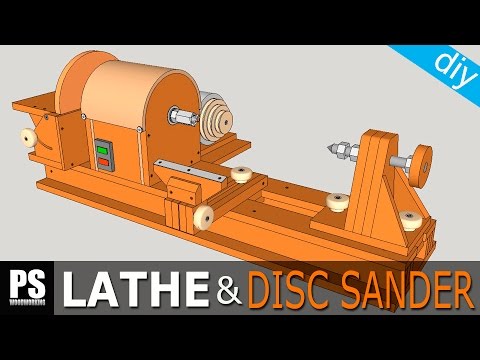

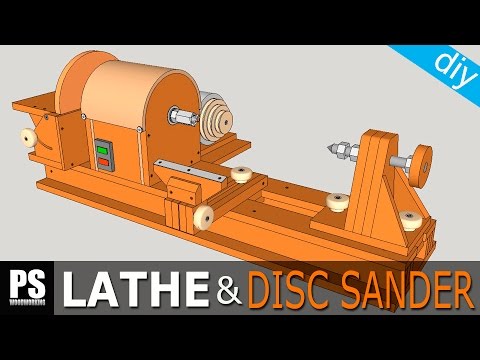

自制車床和圓盤砂光機 Part1 (Homemade Lathe & Disc Sander Part1)

jackylin 發佈於 2021 年 01 月 14 日  沒有此條件下的單字

沒有此條件下的單字US /kəmˈpliːtli/

・

UK /kəmˈpli:tli/

US /ædˈvæntɪdʒ/

・

UK /əd'vɑ:ntɪdʒ/

- n. (c./u.)優勢;優點;利益

- v.t.利用;佔便宜

US /dɪˈvɛləp/

・

UK /dɪ'veləp/

- v.t./i.詳盡闡述;建立;打造;(使)成長;發展;沖洗(底片);罹患;產生;培養;發展