字幕與單字

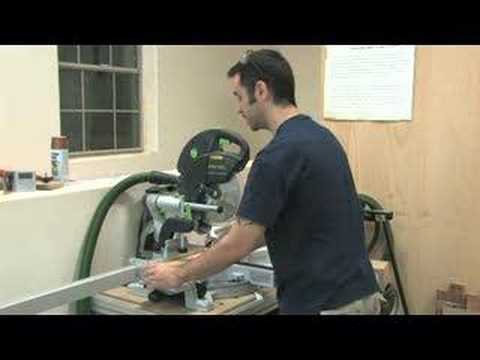

53 - 使用 Festool Kapex 審視斜切鋸的安全問題。 (53 - Reviewing Miter Saw Safety with the Festool Kapex)

00

kuoyumei 發佈於 2021 年 01 月 14 日收藏

影片單字

work

US /wɚk/

・

UK /wɜ:k/

- n. (c./u.)成品;工作的成果;產品;作品;工作;職業;工作(場所);(工作等的)成果

- v.t./i.起作用;行得通;運轉;運作;運行;活動;起作用;有效用;(機器等)運轉;活動

- adj.工作相關的

A1 初級多益初級英檢

更多 compound

US /kɑmˈpaUnd/

・

UK /'kɒmpaʊnd/

- n. (c./u.)複合;化合物;柵欄包圍區;混和物;複合字

- v.t.以複利計算;混合;加重;使惡化;混合;和解

- adj.複合的

B1 中級中級英檢

更多 side

US /saɪd/

・

UK /saɪd/

- v.i.側線 ; 旁軌 ; 外牆

- n.一方;一派;(身體的)一側;(性格的)方面;(事物的)邊緣;(相互對立的)一方

- adj.次要的;次要的(門等)

A1 初級初級英檢

更多 使用能量

解鎖所有單字

解鎖發音、解釋及篩選功能