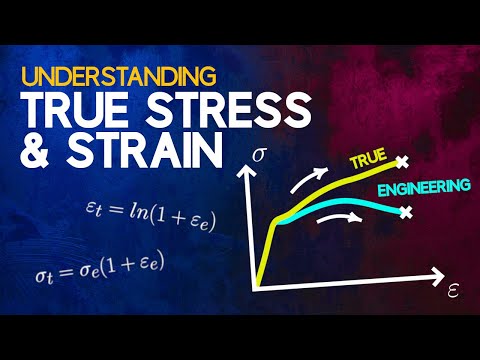

瞭解真實應力和真實應變 (Understanding True Stress and True Strain)

沒有此條件下的單字

沒有此條件下的單字- v.t.裝出;假裝;以為;(想當然地)認為;承擔;就任

US /sɪɡˈnɪfɪkənt/

・

UK /sɪgˈnɪfɪkənt/

US /ˈʌltəmɪt/

・

UK /ˈʌltɪmət/

- adj.最終的;基本的;根本的;最好的;最終的;最大

- n.飛盤爭奪賽;極致;終極

US /məˈtɪriəl/

・

UK /məˈtɪəriəl/

- n. (c./u.)布料;素材;資料;材料;物質

- adj.重要的;物質的