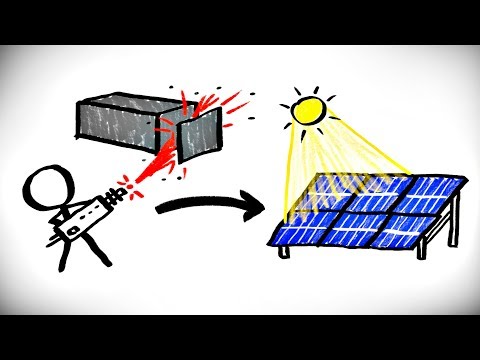

用粒子加速器製造的太陽能電池板? (Solar Panels Made With a Particle Accelerator?!)

Summer 發佈於 2021 年 10 月 08 日  沒有此條件下的單字

沒有此條件下的單字US /məˈtɪriəl/

・

UK /məˈtɪəriəl/

- n. (c./u.)布料;素材;資料;材料;物質

- adj.重要的;物質的

US /tɛkˈnik/

・

UK /tekˈni:k/

- n. (c./u.)技術;工藝;技能;(藝術)技巧

- n. (c./u.)大小;規模;魚鱗;比例;等級;標尺

- v.t./i.測量;攀登;魚鱗